Want to read more? Click here for more Well Insights.

HOW TO RUN A BUILDUP TEST

A buildup test is a common type of well test, which includes pressure transient analysis, and it is used to determine some critical well and reservoir parameters: permeability, skin factor, average reservoir pressure (P*), and the distance to reservoir boundaries. A buildup test is performed by flowing the well to create a pressure drawdown and then shutting in the well to create a pressure buildup. With the data collected, the pressure buildup can be analyzed to determine the well and reservoir parameters above.

Pseudo-Radial Flow

In order for a buildup analysis to be accurate, the well must reach radial or pseudo-radial flow. Pseudo-radial flow occurs when the pressure transients travel far enough out from the wellbore that the fluid flow exhibits the same characteristics as true radial flow. In other words, pseudo-radial flow occurs when the flow in the reservoir is close enough to radial that it can be treated as such. Pseudo-radial flow takes time to form and typically occurs in hydraulically fractured or perforated wells as shown below, whereas openhole completions are more likely to have truly radial flow from the beginning of flow.

As can be seen in the diagram above, the early pressure transients are elliptical as the flow travels into the frac wings. Over time, the pressure transients travel far enough away from the well that they become circular, rather than elliptical. At this point, the flow is considered to be pseudo-radial.

It should be noted that in situations of partial penetration, spherical flow will occur rather than radial flow. In these situations, the same rules apply, but the well will need to be modeled as spherical flow rather than radial flow.

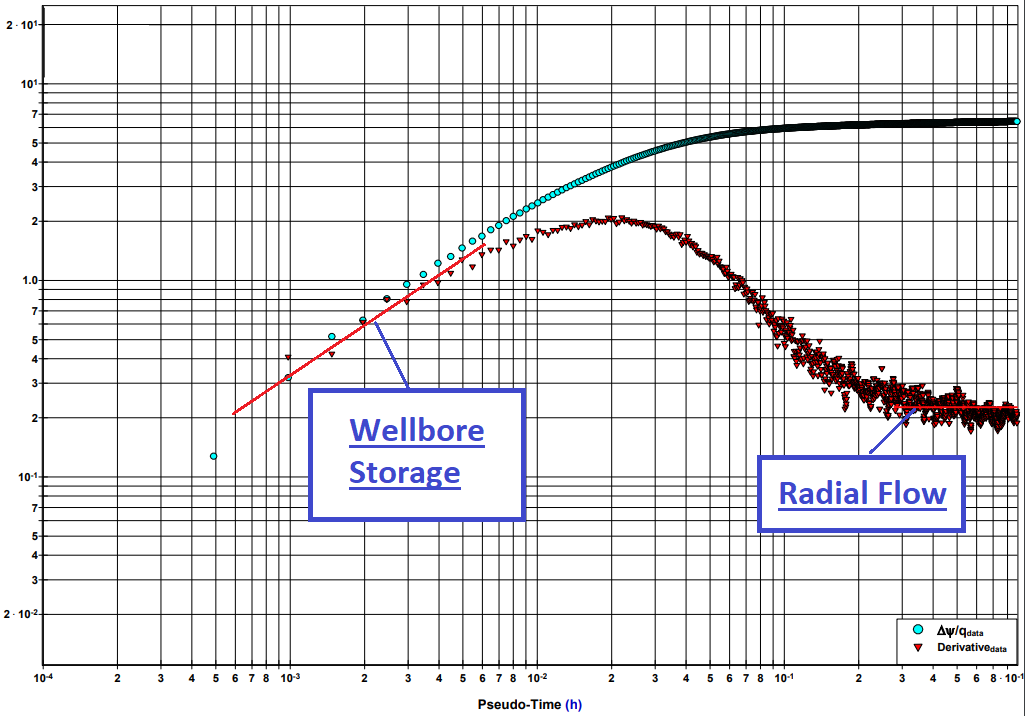

Wellbore Storage

In order to understand pressure transient analysis, we must understand the concept of wellbore storage. Wellbore storage is a phenomenon which occurs when there are compressible fluids, such as gas, in the wellbore. When the well is first opened to flow, the gas in the wellbore expands creating a high flowrate that is not representative of the reservoir. When this occurs, the outflow of fluid from the wellbore to surface is greater than the inflow of fluid from the reservoir to the wellbore. The result is a sharp decline in flowing pressure, which we have all observed when first opening a well. As the well flows over a course of seconds, minutes, hours or even days (depending on the well), the well begins to stabilize, which indicates that the inflow from the reservoir is equal to the outflow to surface. At this point we would say that we are “out of wellbore storage”.

We can estimate the time necessary to be out of wellbore storage with the following equations:

Obviously, if we are performing this calculation before a welltest we will not yet know certain variables, such as permeability and skin factor. In this situation we use an estimate of these variables to try and project what we think the wellbore storage duration will be. This estimate is simply used to tell us a minimum time that we need to test the well so that we can be out of wellbore storage. A general rule of thumb is that we want to test the well for no less than 4 times the wellbore storage duration (twbs).

As previously mentioned, the wellbore storage phase is over when the inflow and outflow of the wellbore fluid is equal. This will result in pressure stabilization. While there is no official definition of stabilization, we use a simple rule of thumb: Stabilization occurs when the well pressure changes at a rate of less than 0.5% per hour. For example, if a well is flowing at 1,000 psi, stabilization occurs when the pressure drop is less than 5 psi per hour, or 1.5 psi per 15 minutes.

Typecurves

Typecurves are an important part of well test analysis and they are used to provide insight into the flow regimes occurring in the reservoir. Typecurves can tell us whether the well is in radial flow, spherical flow, or linear flow. They can also tell us if the formation is naturally fractured, dual-porosity, infinite-acting, or has a constant pressure boundary like an aquifer. Typecurves can also identify the wellbore storage phase, and if the test was ended too early, and pseudo-radial flow was not reached, the typecurve will reveal this.

The image below is an example of a typecurve revealing wellbore storage and radial flow throughout the course of a buildup test:

Considerations For Running A Buildup Test

When performing a buildup test, there are a couple of considerations that should be taken:

1. Near-constant flowrate – The principals of pressure transient analysis assume a constant flowrate is achieved prior to buildup. While there is no such thing as a perfectly constant flowrate, measures should be taken to attempt to keep the flowrate steady for a period of time prior to shut-in.

2. Test Length – We want to make sure that we are beyond wellbore storage when the test ends, to ensure that the data is truly representative of the reservoir. Generally, we want to flow until we reach stabilization, and not less than 4 times t-wbs if we have performed those estimates. After stabilization has been reached, we can end the test, or we can continue the test for a longer period of time to gain a greater radius of investigation.

3. Pressure Gauges – It is highly recommended that any well test involving pressure transient analysis use bottomhole pressure gauges. The analysis is extremely sensitive, and any error created by estimating bottomhole pressure from surface could lead to inaccuracy in the results. Also, any gauges used should have as small of a pressure transducer as possible without overpressuring the gauge. For example, if the maximum bottomhole pressure during a test is going to be 1,000 psi, then 1,500-psi gauges should be used rather than 15,000-psi gauges. This will result in a more accurate analysis.

4. Multiple Payzones – If multiple payzones exist in a well, the zones should be isolated with bridge plugs or packers and tested individually. Otherwise, the results will be skewed and will represent at best some sort of average of all the payzones.

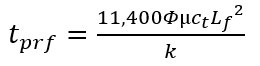

5. Pseudo-Radial Flow – If the well is hydraulically fractured or cased and perforated, an estimate of the time to reach pseudo-radial flow should be done to ensure that the test is not ended prior to pseudo-radial flow being reached. The time to pseudo-radial flow can be estimated with the following equation:

6. Input Parameters – Certain well and reservoir parameters will be required as inputs in order to perform a pressure transient analysis. These parameters include: porosity, pay thickness, fracture half-length, gas, oil, and water saturations, gas gravity or composition, wellbore diameter, well completion information. Some of these parameters will be estimates from core data or offset wells, however, the more accurate the parameters, the more accurate the final analysis.

7. Desired Radius of Investigation – The longer the test, the more of the reservoir you’ll see. If there is a boundary or fault that you want to look at, make sure that you run your test long enough for these items to be within the radius of investigation. You can read more about radius of investigation here.

8. Good Quality Data – Good data is crucial for a good analysis. Be sure that all pressure gauges and flow measurement devices are calibrated and appropriately sized to collect accurate and precise data. Furthermore, make sure that the field personnel performing the test understand the test procedure and that quality-control is a priority. With that being said, here is a shameless plug for FyreRok well testing services. If you want to best data and the most accurate analysis, call FyreRok!

A buildup test is a great way to gain insight into your well. There are many secrets to be revealed, but the test must be strategically designed and well-executed in order to get the most out of it. If you are looking for help planning and executing your next well testing project, FyreRok just a phone call away.

YOU’RE WELL HAS A STORY TO TELL…ARE YOU LISTENING?

Want to read more? Click here for more Well Insights.

You can also subscribe to receive Well Insights updates directly to your inbox.